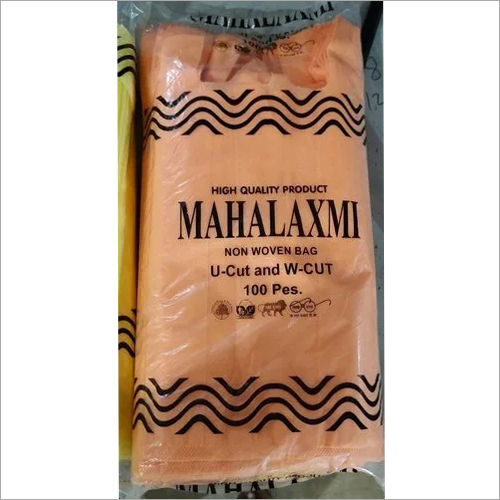

High-quality U Cut Shape Bags, Plain D Cut Non Woven Bag, W Cut Non Woven Bags, D Cut Vergin Nonwoven Bags, Non Woven U Cut Bag, and many more can be availed here at economical rates.

HOT PRODUCTS

Mahalaxmi Packaging Works, established in 2017, is a renowned manufacturer and supplier of a comprehensive range of non-woven bags. Our extensive range includes W Cut Non-Woven Bags, Plain D Cut Non-Woven Bags, Non-Woven U Cut Bags, D Cut Virgin Nonwoven Bags, U Cut Shape Bags, and many more, available in various sizes, colors, and specifications to cater to our customers diverse needs. These bags are highly appreciated in the market for their lightweight, tear resistance, heavy load-bearing capacity, and durability.

With a state-of-the-art and technologically advanced infrastructure facility, we are capable of carrying out the production process with utmost precision. Equipped with modern machinery and technology, our infrastructure is regularly updated to meet our customers bulk demands efficiently. We use high-quality materials such as polyester, nylon, or polypropylene, sourced from reliable vendors in the industry, to manufacture these bags. Furthermore, we have a dedicated team of logistic personnel who ensure timely dispatch of these products to our customers.

Our Excellence

Mahalaxmi Packaging Works is committed to achieving optimal productivity through collaborative teamwork, fostering a positive work culture, and engaging all stakeholders, including our employees, customers, suppliers, and business associates. We aim to work together in a smart and insightful manner to create a harmonious and productive work environment.

Manufacturing Process

Our products, including U Cut Shape Bags, Plain D Cut Non Woven Bags, W Cut Non Woven Bags, D Cut Virgin Nonwoven Bags, Non Woven U Cut Bags, and more, undergo a manufacturing process consisting of several steps:

- Firstly, the raw materials are prepared by blending and mixing them with required additives and colorants.

- Next, the prepared fibers are fed into a web-forming machine, which employs various methods to create a web of fibers.

- The web of fibers is then bonded together using heat, pressure, or chemicals.

- The bonded web is cut into the desired shape and size using automated cutting machines.

- The cut pieces of non-woven material are then sewn together using sewing machines to produce the final non-woven bag.

- Finally, the bags are thoroughly checked for quality and any necessary finishing touches are added.

Quality Control

Our goal is to ensure high customer satisfaction by delivering quality products in a timely manner. We aim to achieve optimal productivity through intelligent and collaborative teamwork, maintaining a positive work culture, and engaging all stakeholders, including our employees, customers, suppliers, and business associates. We strive for zero defects and are committed to moving towards total quality management through continuous employee training, with a focus on continuous improvement.

Why Us?

By providing high-quality products such as W Cut Non Woven Bags, Plain D Cut Non Woven Bags, Non Woven U Cut Bags, D Cut Virgin Nonwoven Bags, U Cut Shape Bags, and others tailored to the precise requirements of our valued customers, we have established a strong presence in competitive industries.

Some of our major factors are:

- Competitive price

- Customization facility

- Client-centric approach

- Wide distribution network

- Quality tested products

We accept orders of minimum 300 Kgs quantity.